Hydrogen storage alloy

Hydrogen storage alloy

Properties of Hydrogen storage alloy

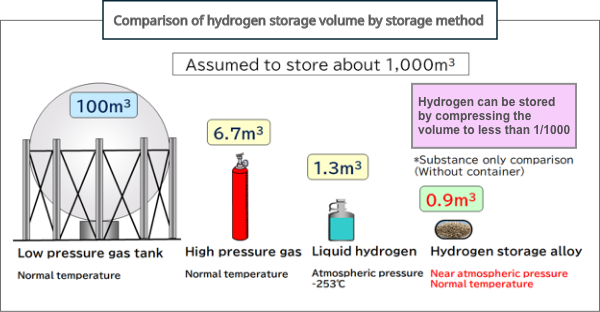

Hydrogen storage alloy are alloys that can compress and store [ less than 1/1000] hydrogen gas as a metal hydride[solid state], and can absorb and desorb hydrogen at low pressures of less than 10 atmospheres(1Mpa)(Not applicable to Japanese High Pressure Gas Safety Law ) It is also one of the most compact and safe storage methods for hydrogen gas.

In the future hydrogen society, this material is ideal for hydrogen utilization in places where safety and security are required or where installation space is limited (for example, city blocks, residential areas, factories, etc.)

Characteristics of our hydrogen storage alloy

Our company has over 30 years of experience in the business of hydrogen storage(absorb) alloys for nickel-metal hydride battery negative electrodes, and in recent years has been developing manufacturing and selling hydrogen storage alloys using the technology and know-how we have accumulated.

Regarding alloy types, we are focusing most of our efforts on TiFe-based hydrogen storage alloys(hereinafter abbreviated as TiFe-based alloy)

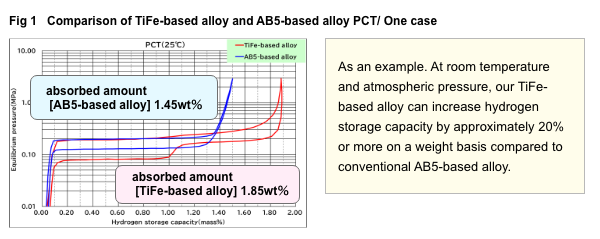

The characteristics of this alloy system include AB5 hydrogen storage alloy(hereinafter abbreviated as AB5-based alloy), which contains a large amount of cheap iron at 40 to 50% as the main raw material, and 60% or more of expensive nickel and cobalt in comparison, raw material costs can be significantly reduced.

Hydrogen storage capacity can be increased by approximately 20% on a weight basis compared to AB5-based alloy(Fig.1) making it ideal for applications that use large amounts of hydrogen in the future hydrogen society.

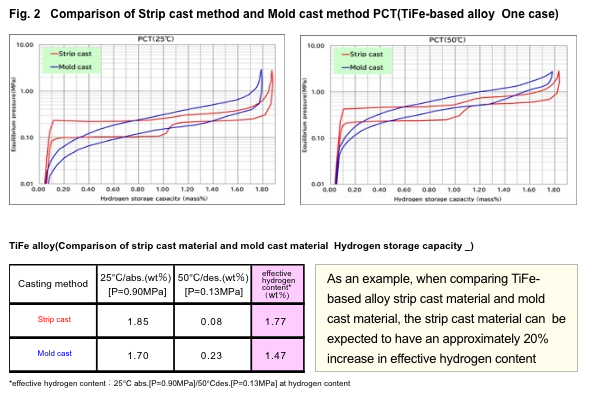

In addition, our hydrogen storage alloy uses a manufacturing method called the strip casting method, it is possible to obtain an alloy with good amount of contained elements and structural uniformity. Due to the uniformity effect, the flatness of the plateau region during hydrogen absorption and desorption is superior to that of general mold cast materials.

As a specific example, here is a PCT diagram of a strip cast material and mold cast material of the same composition(TiFe-base alloy)(Fig. 2)

Compared to mold cast material, strip cast material have a higher hydrogen storage capacity and better flatness in the plateau region, allowing hydrogen to be used until the final stage of absorb. This means that the amount of hydrogen available in the pressure range 0.1~1.0MPa in creases significantly , making it possible to provide more practical alloys.

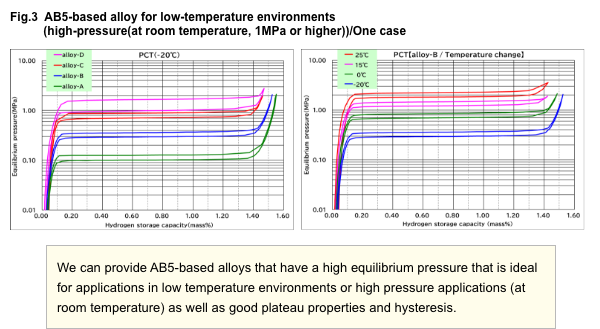

On the other hand, for applications in low-temperature environments or high-pressure applications (room temperature, 1MPa or higher),AB5-based alloy with high hydrogen release pressure can also be provided(Fig. 3)

We believe that these alloys are ideal for applications that require hydrogen release in cold regions or at high pressures.

In addition, we can also provide consultation and customization for alloy production upon request.