About Us

About Our Patents

Patent for hydrogen-absorbing alloys

Information on our hydrogen-absorbing alloy-related patents

Nickel-metal hydride batteries were first completed in 1990 and are one of the main rechargeable batteries currently in circulation today. In that same year, we began the production and sale of rare-earth nickel hydrogen-absorbing alloys, and in 1994 we began producing thin pieces of unidirectional solidified hydrogen-absorbing alloys through our Strip Casting Process. Since then, we have become a major manufacturer of hydrogen-absorbing alloys using the SC Process.

In 1995, we developed La-Mg-Ni based hydrogen-absorbing alloys with an antiphase boundary and released 1), 2) both internally and externally. Our company has provided patent information related to this alloy for your reference. For questions regarding these patents and licenses, please contact our department for intellectual properties.

■Santoku-held SC Process Patents and their Terms of Validity

(an excerpt of our patents)

| Japan | America | Europe | Korea | China | |

|---|---|---|---|---|---|

| La-Mg-Ni Alloy Patent 1) | 2016 | 2016 | 2016 | 2016 | 2016 |

| La-Mg-Ni Alloy Patent 2) | 2016 | 2016 | 2016 | 2016 | 2016 |

| La-Mg-Ni Alloy Patent 3) | 2031 | Under examination | Under examination | Under examination | Under examination |

1)JP 3688716

2)JP 3993890

3)JP 5681729

When purchasing La-Mg-Ni based hydrogen-absorbing alloys

As seen above, our company possesses numerous international and domestic patents related to La-Mg-Ni based hydrogen-absorbing alloys. We recommend that you confirm with the supplier whether the alloy you desire infringes upon Santoku-held La-Mg-Ni based hydrogen-absorbing alloy Patents before purchasing.

When manufacturing La-Mg-Ni based hydrogen-absorbing alloys

Please be aware that, regardless of the intended purpose, manufacturing and sales related to La-Mg-Ni based hydrogen-absorbing alloys may infringe upon Santoku-held La-Mg-Ni based hydrogen-absorbing alloy Patents in regions where these apply.

La-Mg-Ni Based Hydrogen-Absorbing Alloy Properties

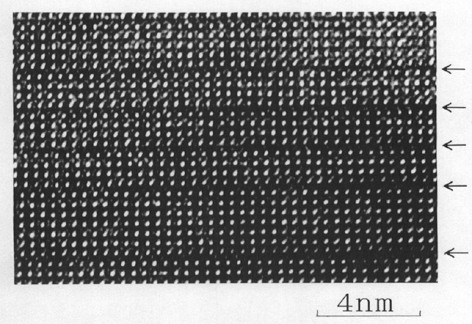

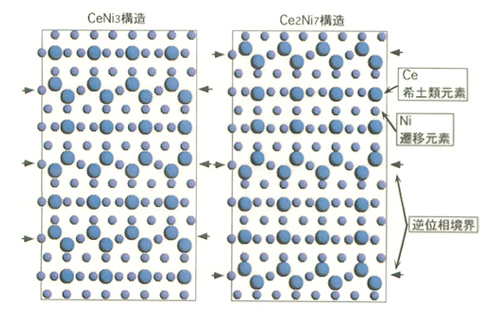

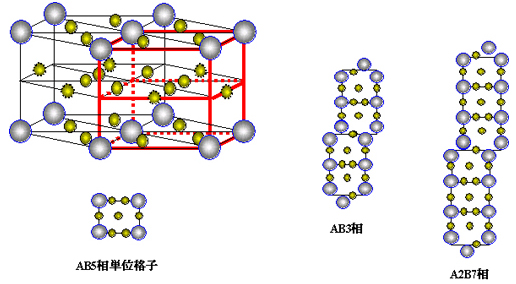

This alloy is notable for its crystalline structure with antiphase boundary. When looking at this alloy under a high-resolution transmission electron microscope, image 3) shown in figure 1 can be seen. With a specified antiphase boundary, this is the LaNi5-type single-phase structure’s crystalline form, and the arrows indicate its antiphase boundary. The white dots of this high-resolution image correspond with the center of the LaNi5-type unit cell. With the assistance of computer simulation in analyzing this high-resolution image, we get the crystalline structure 2) with antiphase boundary shown in figure 2. If an element with an atomic radius bigger than Ni such as rare-earth elements and Mg replaces the specified Ni site of the LaNi5-type unit cell, an antiphase boundary is formed and the regularity of the crystalline structure is altered. According to the amount of elements replaced, the appearance of a LaNi3 phase and LaNi7 phase can be extrapolated from this same figure.

■図1 本合金の高分解能透過電子顕微鏡像3)

■図2(100)面の結晶構造モデル2)

【文献】

1)Akihito Kaneko,Kenji Hiraga:"Microstructure of MmNi5-based alloy for hydrogen storage alloy" , Abstracts of The 117th Meeting of JIM(1995), p.330

2)金子明仁、平賀賢二;「Mm(ミッシュメタル)-Ni系水素吸蔵合金の微細構造」、溶融塩および高温特許No.3688716